80 PLUS: Why You Need Titanium Power Supplies in Your Data Center

Discover the benefits of selecting 80 plus certified power supplies, including cost, greater power efficiency and reliability, and meeting thermal constraints.

PDF herunterladenThe one thing that the largest recent trends in technology all have in common is that they all require tremendous amounts of computing power. Artificial intelligence and machine learning (AI/ML) can require massive amounts of computational power to execute specific algorithms; supercomputers are often used to do the processing. AI/ML also often requires enormous amounts of data to train the algorithms correctly. Like cloud computing, storing and processing this information requires data centers full of servers, routers, and switches - all of which consume large amounts of power.

EFFICIENCY IS INCREASINGLY IMPORTANT IN HIGH PERFORMANCE COMPUTING

This new generation of computing is placing stringent demands upon the components and systems needed to run these machines. Of utmost importance in all these computing applications is the power supply. It is no longer enough to “just” provide power. Thermal constraints must be met, greater power efficiency must be achieved, redundancy must be put in place, and high reliability is required.

Any well-designed computing system will take all these factors into account. In fact, regulations and certifications are beginning to govern some of these requirements and help identify power supplies that meet certain criteria.

One such example is 80 PLUS. It sets stringent requirements for power supplies, ensuring their energy efficiency. The specifications demand that the power supplies achieve at least 80% energy efficiency at various load levels - 20%, 50%, and 100%. For instance, to qualify for the basic 80 PLUS certification, a power supply must perform at 80% efficiency at the specified loads. The standards become progressively stricter for higher certifications like Bronze, Silver, Gold, Platinum, and Titanium.

WHAT IS THE 80 PLUS PROGRAM?

The 80 PLUS program is a certification program launched in the early 2000s. It was first put together by Ecos Consulting but is now run by CLEARResult. It is a voluntary program that helps manufacturers promote energy-efficient designs intended for use in computers. In order to meet the 80 Plus certification, power supplies must be at least 80% efficient at 20%, 50%, and 100% of the rated load and achieve a power factor of 0.9 or greater at 100% load.

But what exactly are power efficiency and power factor?

CALCULATING POWER SUPPLY EFFICIENCY

Power efficiency may be the more well-known measurement of the two. Simply put, power supply efficiency is the ratio of output power to total input power, expressed as a percentage.

Equation 1.

Efficiency [%] = x 100

Due to the non-ideal effects of electronic components used in power supplies, 100% efficiency is not possible. These effects can be the switching and conduction losses in active components, such as transistors and rectifiers, resistive losses in wires, windings, PCB traces, and ac losses in the transformer. The energy lost in these components is generally dissipated in the form of heat, which can create additional issues.

CALCULATING POWER FACTOR

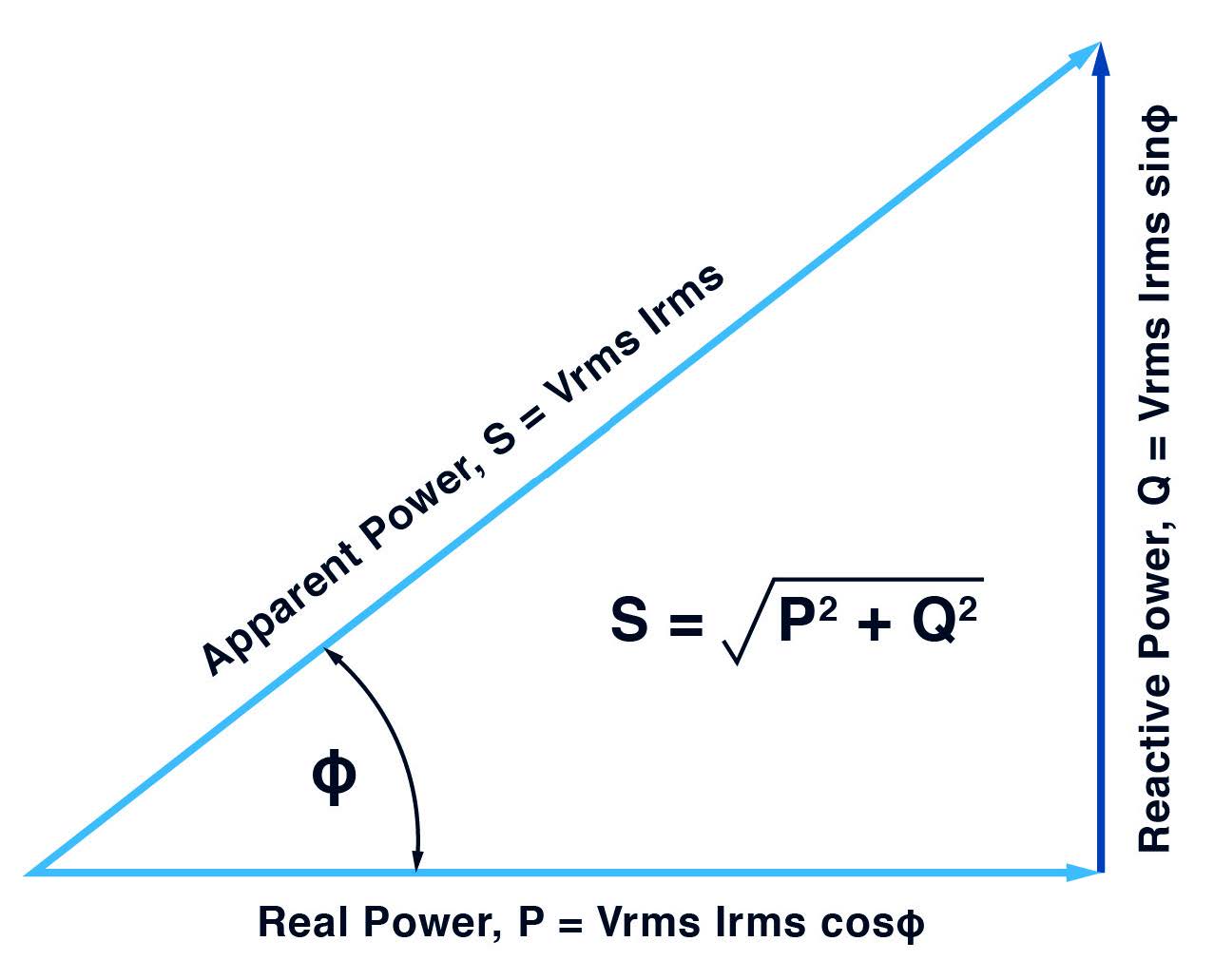

Power factor is a bit more complex. It is a ratio of real power to apparent power and has a maximum value of one. Real power, measured in watts, refers to the power that does work and is consumed by the power supply and load. 90 degrees out of phase with the real power is reactive power, measured in volt-amps reactive (VAR). Reactive current simply circulates in the system doing no work. Apparent power is the magnitude of the vector sum of the real and apparent power, which is also equal to the product of rms voltage and current.

Figure 1. Power triangle showing real and reactive components and resulting apparent power vector.

Equation 2.

Power Factor =

In a purely resistive circuit, the power factor is 1 and all of the apparent power produces work. However, when reactive components such as inductors and capacitors are introduced into circuits and loads, the current waveform will shift with respect to the voltage and the power factor will drop due to the addition of reactive power. In non-linear circuits, such as switching power supplies, there are also harmonics to worry about. Harmonic current is reactive and therefore also lowers power factor.

The impact of low power factor is increased input current. This leads to larger and more expensive cabling and distribution networks, reduced capacity on branch circuits, and increased cost.

There are many reasons a designer would choose an 80 Plus certified power supply over others that are not certified. A large reason is cost. Higher efficiency supplies translate into less wasted power. This means more efficient power supplies can help reduce the cost of running larger facilities. Wasted power is generally dissipated in the form of heat, often necessitating cooling systems that not only add cost but can take up precious space and create unnecessary noise. Less heat and fewer (or no) running fans also help extend a product’s life and the overall reliability of a system.

80 PLUS Efficiency Levels

As the name implies, when the 80 Plus certification was first introduced, it only required that power supplies be at least 80% efficient at 20% load, 50% load, and 100% load. This level of efficiency is now known as 80 Plus Basic. Since the program’s introduction five additional levels of certification have been added. The 80 Plus program now consists of the following levels of certification:

Abbildung 2. Current 80-Plus Levels.

Each of these certifications is further divided up into sub-categories based on AC input voltage. This helps manufacturers target different regions of the world. These subcategories include 115V internal non-redundant, 230V internal redundant, 115V industrial, 230V EU internal non-redundant, and 380V DC.

The different levels of certification, along with 3 of the different sub-categories, are outlined in the table below. It is also worth pointing out that the highest level of certification, 80 Plus Titanium, introduced an additional rated load of 10%.

Power supplies are generally the most efficient between 50% and 75% of their rated loads. However, at lighter loads, power supply efficiency can drop significantly. Indeed, with the exception of Titanium rated supplies, any 80 Plus certified supply can drop below 80% efficiency at loads below 20%. With that said, the Titanium level of certification requires that all supplies be at minimum 90% efficient at 10% of their rated load.

Table 1. 80 PLUS efficiency levels for internal ac/dc power supplies

| 80 Plus Test Type |

115 V Internal non-redundant |

230 V Internal redundant |

230 V EU Internal non-redundant |

|||||||||

| % of rated load | 10% | 20% | 50% | 100% | 10% | 20% | 50% | 100% | 10% | 20% | 50% | 100% |

| 80 PLUS | N. v. | 80% | 80% | 80% | - | - | - | - | - | 82% | 85% | 82% |

| 80 PLUS Bronze |

N. v. | 82% | 85% | 82% | - | 81% | 85% | 81% | - | 85% | 88% | 85% |

| 80 PLUS Silber |

N. v. | 85% | 88% | 85% | - | 85% | 89% | 85% | - | 87% | 90% | 87% |

| 80 PLUS Gold |

N. v. | 87% | 90% | 87% | - | 88% | 92% | 88% | - | 90% | 92% | 89% |

| 80 PLUS Platinum |

N. v. | 90% | 92% | 89% | - | 90% | 94% | 91% | - | 92% | 94% | 90% |

| 80 PLUS Titanium |

90% | 92% | 94% | 90% | 90% | 94% | 96% | 91% | 90% | 94% | 96% | 94% |

IMPORTANCE OF HIGH EFFICIENCY

Reducing power consumption – being green or environmentally friendly – is a benefit in itself, but improving the efficiency of power supplies is also important for cost. Server farms and data centers can save a substantial amount of money by integrating more efficient power supplies into their systems.

Wasted power is calculated with the following equation:

Equation 3.

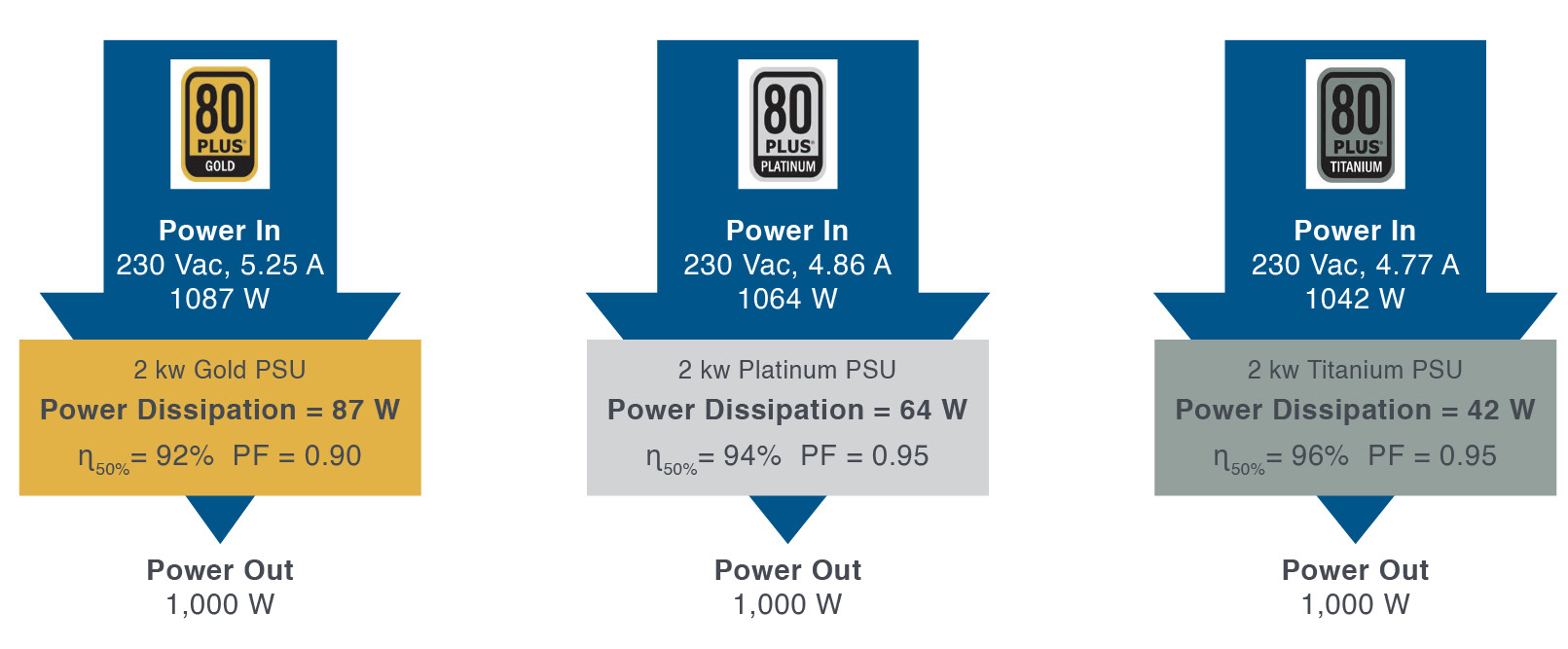

So, for example, a 1000 W supply Gold certified supply would waste 87 W of power at full load. This assumes a 230V non-redundant supply with 92% efficiency. On the other hand, an equivalent 1000 W supply that is Titanium rated (96% efficiency) would waste only 42 W of energy, a 52% reduction in power dissipation.

There are 8,760 hours in a year. Assuming the power supply is being run the entire time, we can calculate the total energy consumed per year in kWh as (1000 W + 87 W) * (8760 hours/year) / (1000 W/ kW) = 9522 kWh/year.

Similarly, for the 96% efficiency supply, it would equate to 9128 kWh. At about $0.15 per kWh, the difference of 394 kWh per year may not seem like much at first (about $59 per power supply per year), but remember, we are only comparing a single supply. Data centers and server farms have thousands of racks of equipment, each requiring multiple power supplies. The cost savings begin to add up very quickly and can easily reach hundreds of thousands of dollars.

Abbildung 3. Comparison of power dissipation between platinum and titanium rated power supplies.

THE FUTURE OF HIGH-EFFICIENCY POWER SUPPLIES

As computing centers become larger and applications become more demanding, high-efficiency power supplies will be more important than ever. They will not only help with cost savings and reliability, but they will help make the systems possible by reducing the heat and space needed. Some of the ideal solutions include power supplies such as Bel Power Solutions line of Titanium certified power supplies.

Figure 4. TEC1300, TET1500 & TET3600 AC-DC front end power supplies.

Bel Power Solutions offers 14 families of power supplies and over 30 products that all meet the Titanium 80 Plus level of certification. Bel’s extensive experience designing electronics allow Bel to offer one of the widest selections of Titanium certified front-end designs. If something different is needed, Bel Power Solutions also provides the option for custom power supplies. Customers can reach out to have a custom solution designed to meet their specific requirements.

View Bel's Front End Titanium Efficiency Power Supplies

EXPLORE PRODUCTS